Dependable and Efficient Storage Solutions

Heavy Duty Racking Systems

Racking System

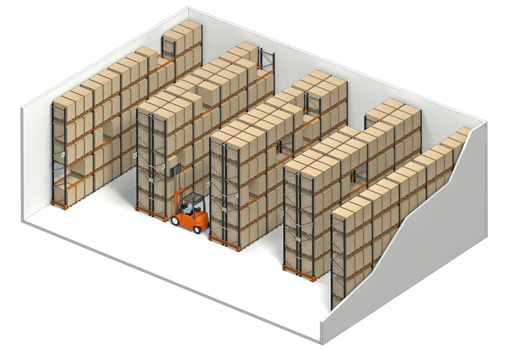

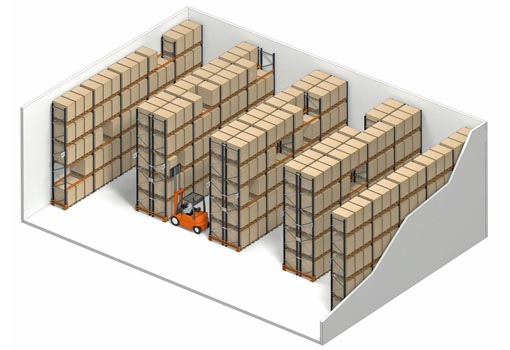

Conventional - Selective Pallet Racking

Conventional or Selective Pallet Racking is the most commonly used and well-accepted racking system that involves placing materials on pallets. This system is versatile and can store a wide range of items of different sizes by adjusting the height of levels with the help of slots available at every 50mm or 75mm pitch. It provides 100% accessibility to each pallet, allowing for smooth stock rotation.

Conventional Pallet Racking system is suitable for storing food materials, chemicals, cold storage, and logistical warehouses. While it is simple and cost-effective, it has a limitation of low efficiency in terms of floor space utilization, as low as 35%. Alternatives such as Drive-In systems or mobile systems can be considered for higher storage efficiency.

Racking System

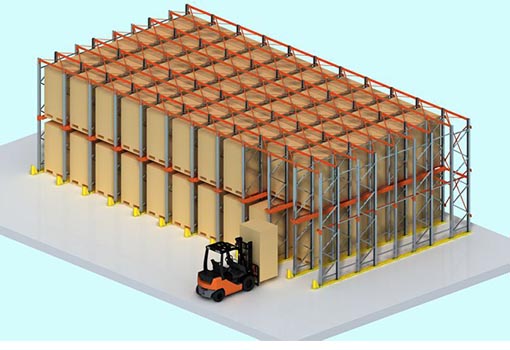

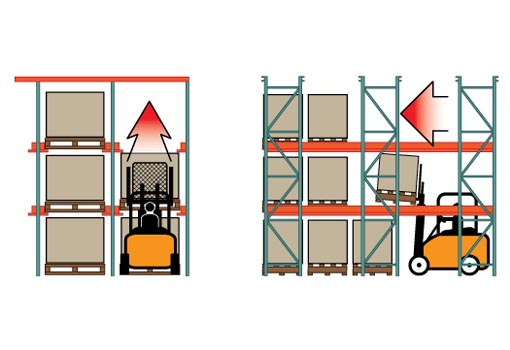

Drive-In Pallet Racking System

Drive-In Pallet Racking allows for very compact storage by eliminating manoeuvring aisles and optimizing over 75% of the available area. It offers limited selectivity and can be used for large SKUs of the same articles.

Additionally, Drive-In Pallet Racking it can be designed as either FIFO (First In, First Out) or LIFO (Last In, First Out) systems. The material handling equipment used includes ECB and special Reach trucks.

Racking System

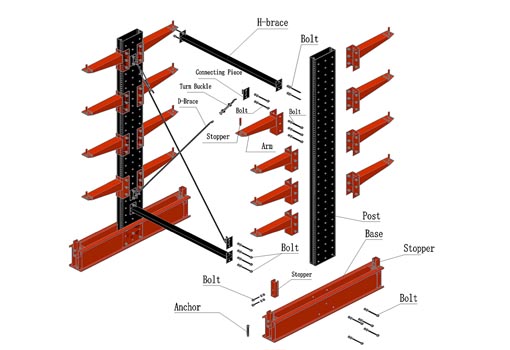

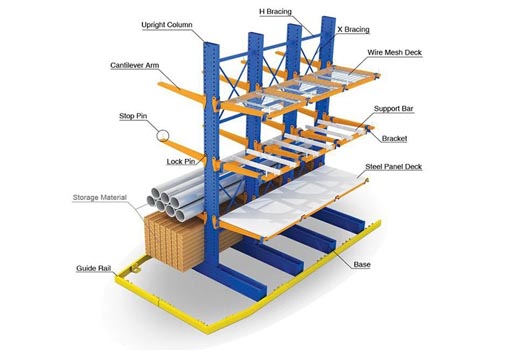

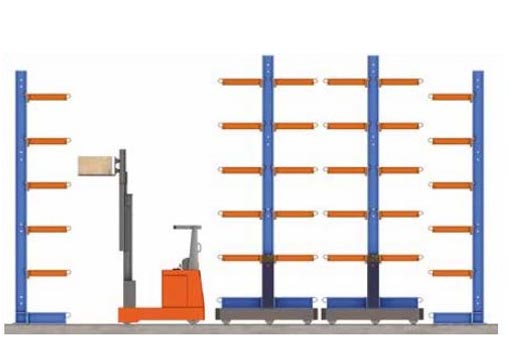

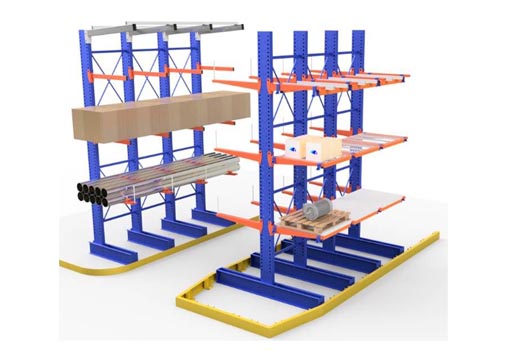

Cantilever Racking System

The Cantilever Racking System is specifically designed for storing long items such as beams, pipes, metal profiles, wood, carpets, and textiles. It is constructed using a sturdy base, vertical columns, and distinctive cantilever arms.

Under the Cantilever Rack System, loading can be accomplished using various lifting systems such as cranes, side loaders, and standard Material Handling Equipment (MHE).